ul.tick {

list-style-image: url(/-/media/New-Corporate-Folder/DUK/Discover-images/Blog/2019/Checklist-17-considerations-for-successful-EWM-and-MOM-intergration/icontick2.ashx??v=a6c3ba9f77914c90b6a4884b34680f51);

margin-top:30px;

}

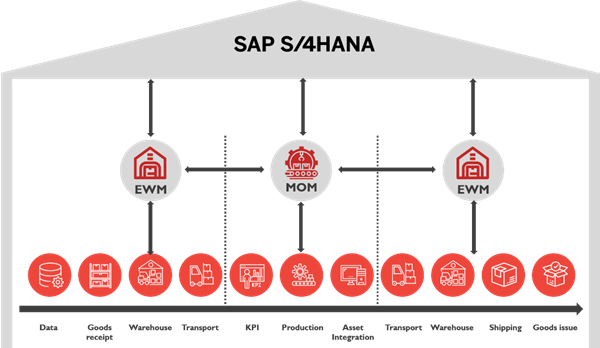

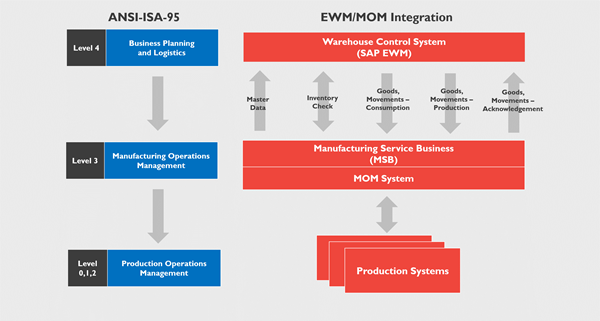

Global SAP EWM & MOM implementations require the project teams to consider many complex design and implementation aspects. We have detailed here, 17 key areas that should be considered carefully during these phases of a project to ensure a fully operational integrated solution delivering the desired productivity and efficiency benefits;

Architecture

Architecture

- MOM system strategy defined; one per site vs a single global instance?

- Master and slave systems modelled for flow of master and transaction data between SAP EWM & MOM

- Performance constraints considered in the integration design for fast moving production lines

Data

Data

- Source system for material master and packaging specifications information defined

- Define frequency of master and transaction data updates across systems; real time or periodic processing?

- Global SAP Handling Unit number range strategy specified; especially when operating across multiple global independent MOM systems

- MOM & EWM case and pallet handling unit nesting and integration design confirmed

Operational use

Operational use

- Batch, shelf life, material number, pallet/case numbers and quantities aligned across SAP EWM & MOM

- Method of MOM data entry evaluated and confirmed; Manual user input, scanning, RFID or automated scanning?

Labelling

Labelling

- MOM & EWM label printing approach defined for end of line print and then optional reprinting of labels

- MOM end of line scanning and printing data elements and sources specified

- A single standard set of labels enabled to support the EWM & MOM design

Testing Execution

Testing Execution

- Full end to end integration test scripts defined covering both EWM & MOM

- End to end integration and performance testing undertaken by Business Users, using real time data

- Operational performance testing executed when validating the EWM & MOM connectivity

Error handling

Error handling

- EWM & MOM integration error validation and controls defined

- Systems error monitoring strategy confirmed

Successfully delivering this definitive list of actions will ensure a solid design foundation when integrating and delivering MOM and SAP EWM warehouse solutions, and ultimately help ensure you achieve productivity and efficiency with your warehouse operations.

/blog_3_720x360-(1).webp?mode=autocrop&w=320&h=240&attachmenthistoryguid=e58449dd-eb93-47fd-95b7-68a3c858da0a&v=&focusX=483&focusY=139&c=3c8cb7b38497bd1d59459f6171f3e647b044f670762500e1c7f4819b158590b0)