/How-to-manage-Supply-Chain-Disruption-crop-720x360-(1).webp?mode=autocrop&w=320&h=320&attachmenthistoryguid=3d82fca0-bb7f-449a-9ffb-985980d87516&v=&c=ec58ce20cb9ff146eeaca09fcbe6df0fe58b09d93a942ebca3d3b141d302df83)

How to manage Supply Chain Disruption with Integrated Business Planning

- operations

- IT

- automotive

- SAP

/How-to-manage-Supply-Chain-Disruption-crop-720x360-(1).webp?mode=autocrop&w=320&h=320&attachmenthistoryguid=3d82fca0-bb7f-449a-9ffb-985980d87516&v=&c=ec58ce20cb9ff146eeaca09fcbe6df0fe58b09d93a942ebca3d3b141d302df83)

Empty supermarket shelves due to panic buying, exports from China stopped, deliveries halted at borders and countries in full lock-down. Demand on non-essential goods and services frozen, air travel and car manufacturing just to mention a few. On the other hand, consumption and demand for Personal Protective Equipment (PPE) used in hospitals by front-line workers and care-homes sky-rocketed to hundreds of thousands of units a day in the UK alone.

As vaccine and various drugs are being developed, and countries around the world start to lift restrictions, certain industries are coming back online and supply chains are starting to operate again. While the pandemic isn’t over yet, expect countries to move lock-down horizons and other restrictions to temper virus transmission. Life and business as we know it will change, but we don’t yet know to what extent, or for how long.

Next generation, cloud based supply chain planning solutions may be the answer. SAP Integrated Business Planning (IBP) for Sales and Operations Planning has real-time simulation ‘what-if’ scenario capability embedded. Place a distortion (upside or downside) on your demand or supply signals and see the impact on your network and its financial impact. Close or squeeze supply in your network, the impact is shown instantly and all in a familiar interface, Microsoft Excel. Want to add some graphics? Use the embedded analytics or Microsoft Excel itself. As all these simulations run at the same time within the same model, an impact analysis throughout the supply chain becomes visible.

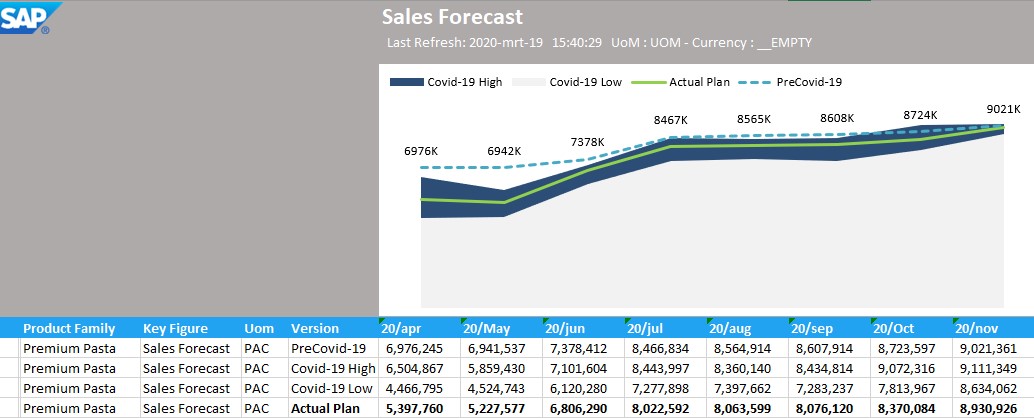

The example above is of a supply chain disruption, such as Covid-19, impact simulation on a product family. An inflated demand signal (Covid-19 High) versus a downside demand signal (Covid-19 Low) compared against a Pre-Covid-19 demand signal, shows clearly that overall demand has dropped during this crisis for the product group. It is projected that sales will improve around July and fully recover around November.

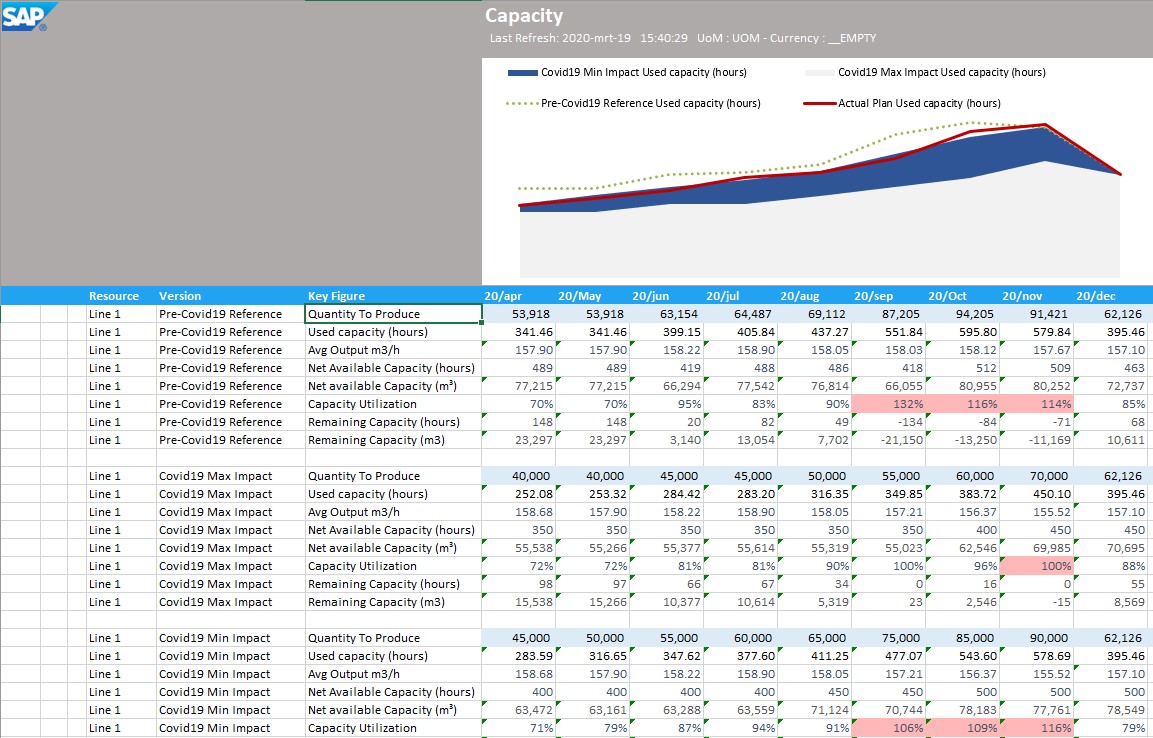

The above image shows another example, this time of a capacity simulation, where 3 different resource constraint scenarios are compared. This simulation simulates labour resource constraints, where line operators are self-isolating or contracted the virus. This clearly impacts the available capacity hours.

We understand that each supply chain is different, each company has different goals set for different horizons, financially or quantitively, and we cannot predict what the future supply chain will look like, if more disruptions occur worldwide. We can however help businesses to simulate or improve the supply chain network resilience, using SAP’s next generation supply chain planning solutions. Having the ability to almost instantaneously test and forecast different scenarios puts you in a significantly stronger position than your competitors when it comes to managing uncertainty.

SAP Integrated Business Planning can provide your organisation with a real-time view of what is happening in the supply chain. To find out how we’ve done this for manufacturers across the globe, post a reply to this article and I’ll get in touch.

Please visit https://www.linkedin.com/pulse/supply-chains-risk-how-get-most-out-your-sop-tool-kristof-de-backer for more info around S&OP.

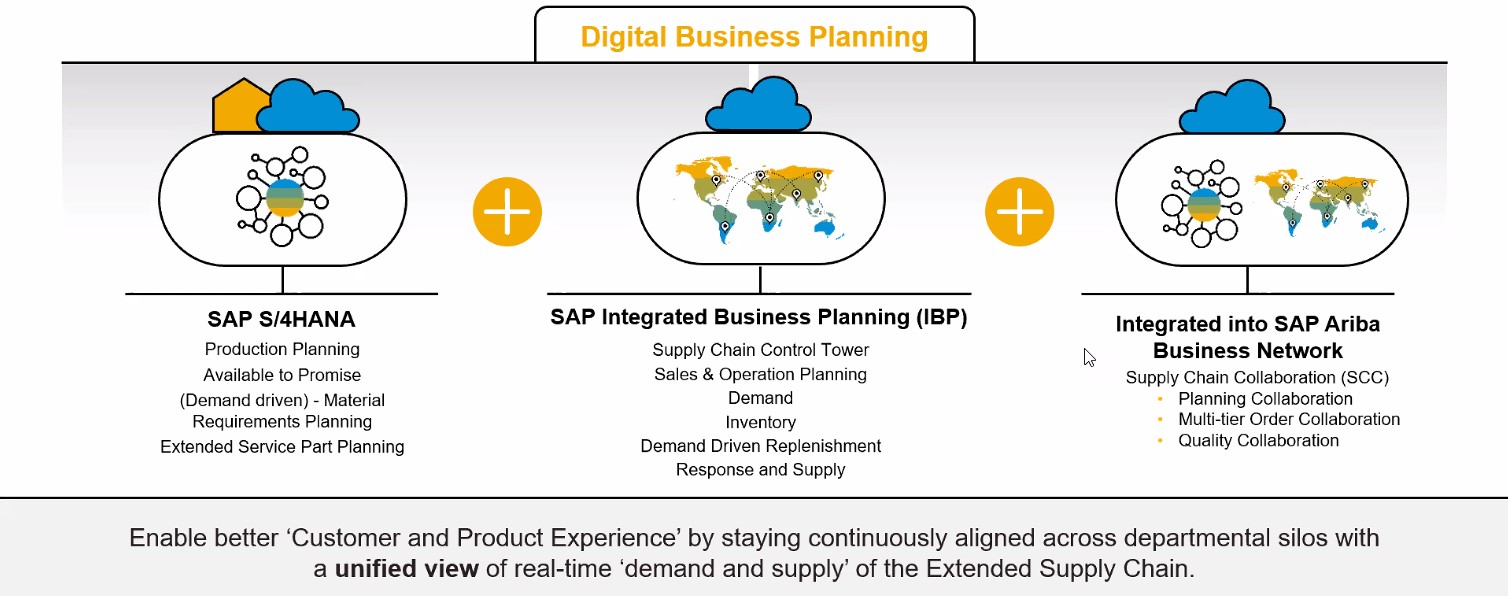

SAP IBP is the centre within SAP’s Digital Business Planning solutions. SAP S/4HANA (ERP) acts as the Enterprise Digital Core but also providing site based planning solutions like Production Planning and Detailed Scheduling, (DD)-MRP or Available to Promise. Extend the supply chain interaction, sharing planning information with customers and/or suppliers, leveraging the SAP Ariba Business Network options.

Please click below for more info about delaware's SAP IBP capability